Messer - Nitrogen generation - PSA (Pressure Swing Adsorption) - Strategic application technology

Breadcrumb

PSA - top

PSA

PSA units – air is all you need

NItrogen GENERATOR top

PSA

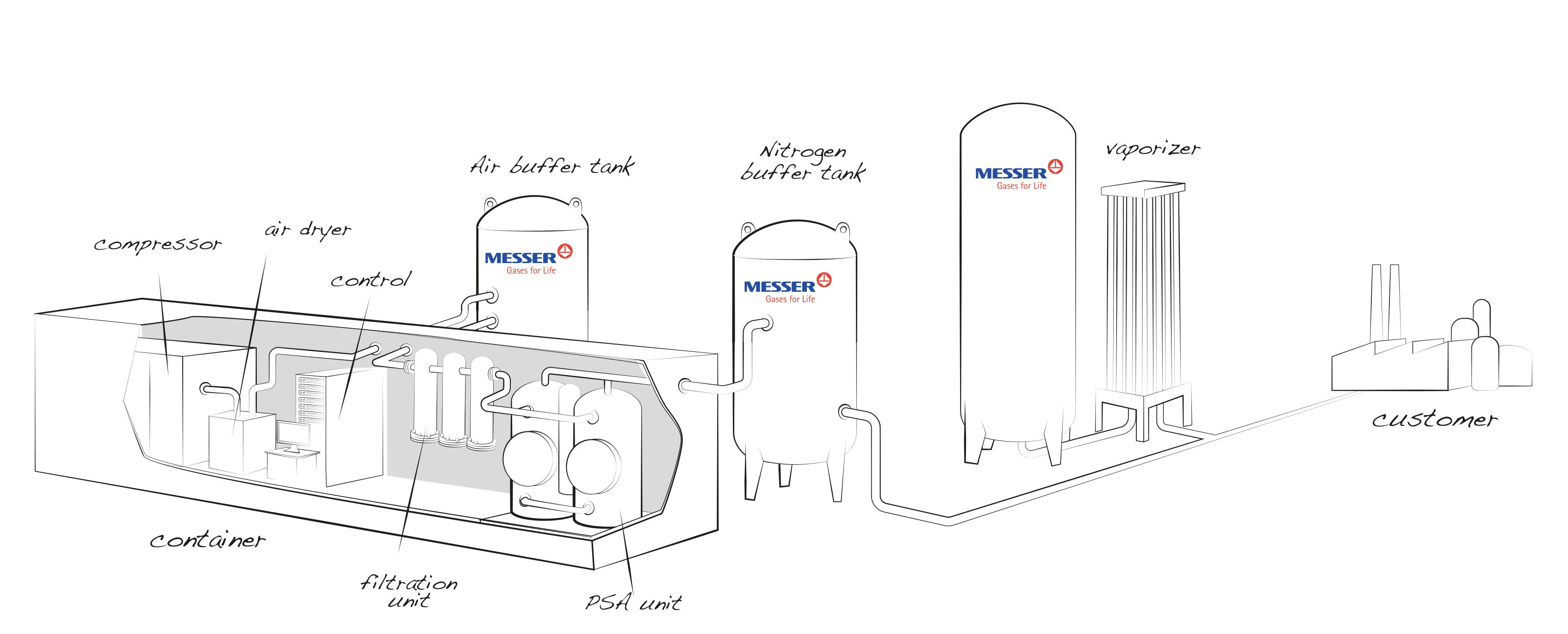

The PSA (Pressure Swing Adsorption) process is based on the physical adsorption properties of specially treated molecular sieves. PSA units only need clean, dry air in order to generate N2 cost-effectively and with purities of up to 99.9% (nitrogen). This air is compressed up to 10 bar, purified and then passed through vessels filled with the carbon molecular sieves (CMS). A continuous nitrogensupply is achieved by switching the gas stream: while one vessel is in operation, the other is regenerated by reducing the pressure. The unwanted gas components are released into the atmosphere.

The plant layout is based on the Messer safety and reliability philosophy which has been applied for over 20 years in operating air separation plants for the supply of customers world-wide.

The nitrogen generator has been designed for the ease of operation (under normal conditions) and low maintenance. In order to minimize personnel and operating costs, all equipment and process controls will be operated and monitored by a computer control system.

The plant will be designed according to the latest international rules and regulations.

Nested Applications

NItrogen GENERATOR PSA

NITROGEN GENERATOR

- Capacity: 250 up to 1 500 Nm3/h Nitrogen

- Purity: 95 – 99.9% (5 to 0.1% O2)

- Supply pressure 4-10 bar(g)

- Operating range: 100-80%

- Low specific power: 0,3 -0,6 kWh/Nm³

- Modular Design feasible

Nitrogen GENERATOR benefit

Benefits for our Customers:

- Low long-term operating cost

- Designed for 24x7 operation

- Safe, reliable, simple to operate, easy to maintain

- Short construction time

- Significant Reduction of CO2 emissions

PROCESS DESCRIPTION

PROCESS DESCRIPTION

Nitrogen GENERATOR back up

Reliable backup supply

A secure supply from a backup source – just in case it is ever needed – is the icing on the cake of any onsite concept, allowing the consumer to sleep easy with regard to the gas supply, even when there are maintenance downtimes, power cuts or other unforeseeable events. Our regional logistics network with centrally managed Europe-wide coordination, combined with sophisticated production planning, ensures that every single customer receives a reliable supply of technical gases from Messer, even during planned and unplanned downtimes.

Messer will provide a tailor-made solution according to your requirements and wishes

APPLICATIONS of PSA 2606

APPLICATIONS

The nitrogen produced by the PSA nitrogen generator is ideal for the chemical, oil and gas, automotive, pharmaceutical, agricultural and food industries, electronics and other industries including production of lithium-ion batteries.

Based on the requirements, wishes of the client and the agreed conditions, the PSA nitrogen generator with a backup system will be installed on the client's territory. The system allows to guarantee the continuous supply of the customer's production with gas of the required volume and pressure

Flow diagram for the PSA unit

Flow diagram for the PSA unit

VPSA our goal

Our goal is to provide you with uninterrupted supply to your production at low production costs and reduced CO2 emissions with the Nitrogen parameters you require, such as constant temperature and Nitrogen pressure.

MESSER is chosen by thousands of customers around the world

Asset Publisher

Teaser PSA

Contact form for every page

Contact us

select action