Octafluoropropane – C3F8 – Quality & Service – Messer - Specialty Gases

Breadcrumb

Octafluoropropane - Banner

OCTAFLUOROPROPANE C3F8

Products and applications of Octafluoropropane

Nested Applications

Octafluoropropane - Part 1

Octafluoropropane

Octafluoropropane (C3F8, also known as Perfluoropropane) is a colorless gas with an ethereal odor which is neither flammable nor toxic. Its alternative name already indicates C3F8 to be the perfluorocarbon counterpart to Propane, replacing all Hydrogen bonds with Fluorine atoms. Its boiling point is at -36,7 °C (236,5 K) and the density of C3F8 gas amounts to 8,047 kg/m³ at 15 °C / 1000 mbar. Due to its relatively low vapor pressure of 7,67 bar (at 20,0 °C), Octafluoropropane exists almost exclusively in its liquid phase within a compressed gas cylinder.

Octafluoropropane - Part 2

INDUSTRIAL MANUFACTURING OF OCTAFLUOROPROPANE

Octafluoropropane is synthesized exclusively via carbon- and fluorine-based reactants, respectively, as there are no natural sources for any fluorocarbon molecules on earth. Two different ways have been established to produce C3F8 gas on an industrial scale: Electrochemical fluorination on the one hand, where Hydrogen Fluoride is employed as a solvent as well as a source for fluorination via electrosynthesis; and the Fowler Process on the other hand, where Cobalt(III) Fluoride is utilized to fluorinate the corresponding hydrocarbon by fully replacing the Hydrogen atoms with Fluorine.

Purchase High Purity Octafluoropropane

High Purity Octafluoropropane

OCTAFLUOROPROPANE 5.0

| Composition | |

| C3F8 | ≥ 99.999 % |

| Impurities | |

| O2 | ≤ 2 ppmv |

| N2 | ≤ 5 ppmv |

| CO2 | ≤ 5 ppmv |

| CxFy | ≤ 60 ppmv |

| H2O | ≤ 3 ppmv |

| HF | ≤ 0.1 ppmv |

Octafluoropropane - Part 3

APPLICATIONS OF OCTAFLUOROPROPANE

While Octafluoropropane is used as a refrigerant under the name R-218, high purity C3F8 gas is mainly adopted in two plasma applications in the semiconductor industry: C3F8 plasma etching of wafers and C3F8 plasma cleaning of vacuum chambers. For the former, Octafluoropropane can be utilized in various etch processes, e.g. for selective C3F8 plasma etching of Silicon Dioxide or as an etching agent for Reactive Ion Etching. For the latter, its Fluorine-to-Carbon ratio (8:3) allows for an efficient cleaning process of the vacuum chambers via C3F8 plasma. Examples for such a C3F8 plasma treatment are sketched below.

Nested Applications

Octafluoropropane - Etching

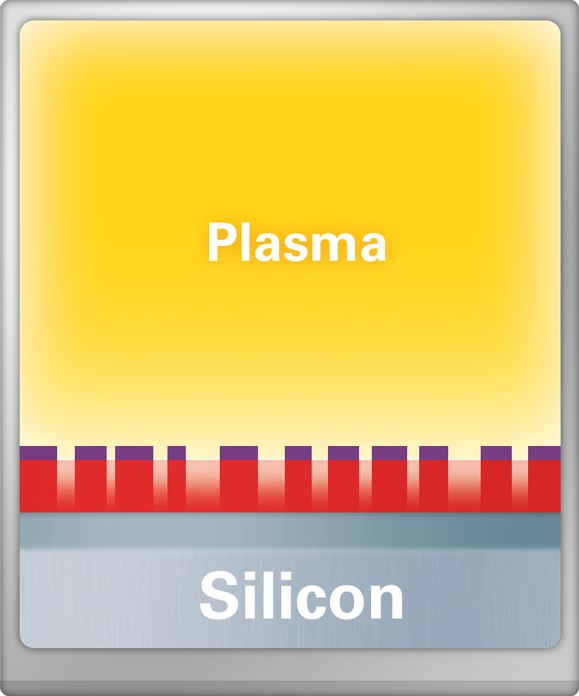

C3F8 plasma etch

High purity Octafluoropropane is an excellent etchant for specific etch applications, either via selective C3F8 plasma etching of SiO2 or applied in Reactive Ion Etching.

Octafluoropropane - Cleaning

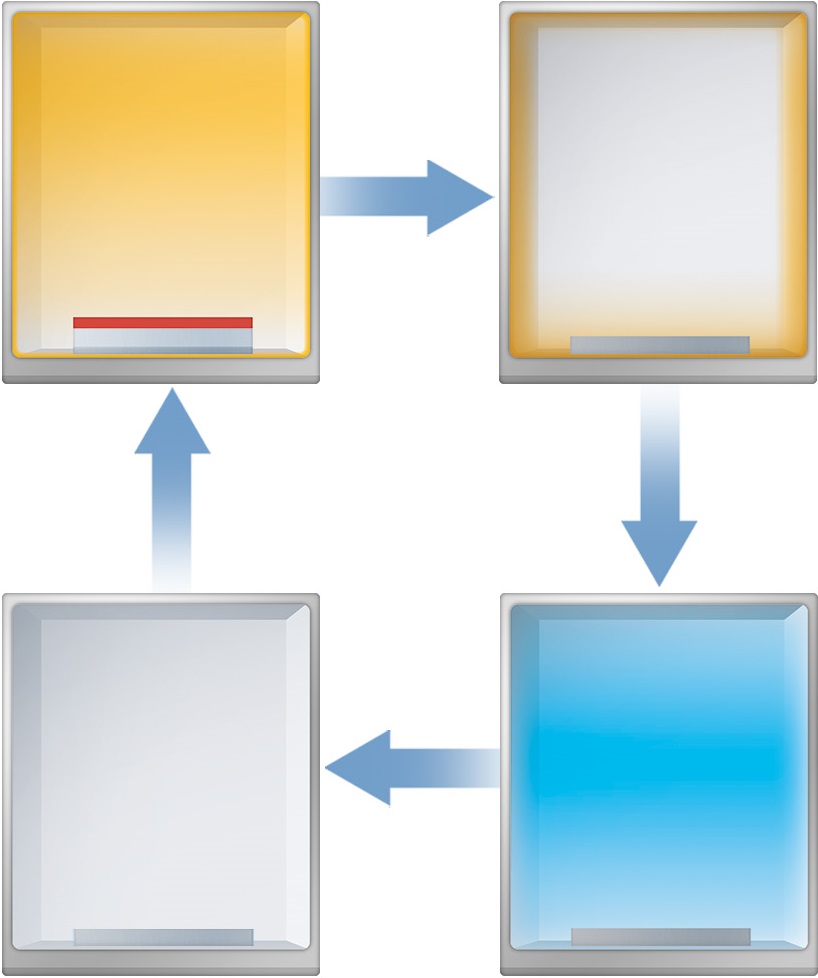

C3F8 plasma cleaning

A contaminated vacuum process chamber can be cleaned efficiently by means of a C3F8 plasma treatment due to its relatively high Fluorine-to-Carbon ratio (8:3).

ESG Main Page - Banner

ELECTRONIC SPECIALTY GASES

High quality gases for the Electronics Industry