Gases the easy way – Messer provides solutions - Strategic application technology

Breadcrumb

Customer segment aluminum

Aluminum production

a $71 billion dollar per year industry

Aluminum melting process

Aluminum melting process

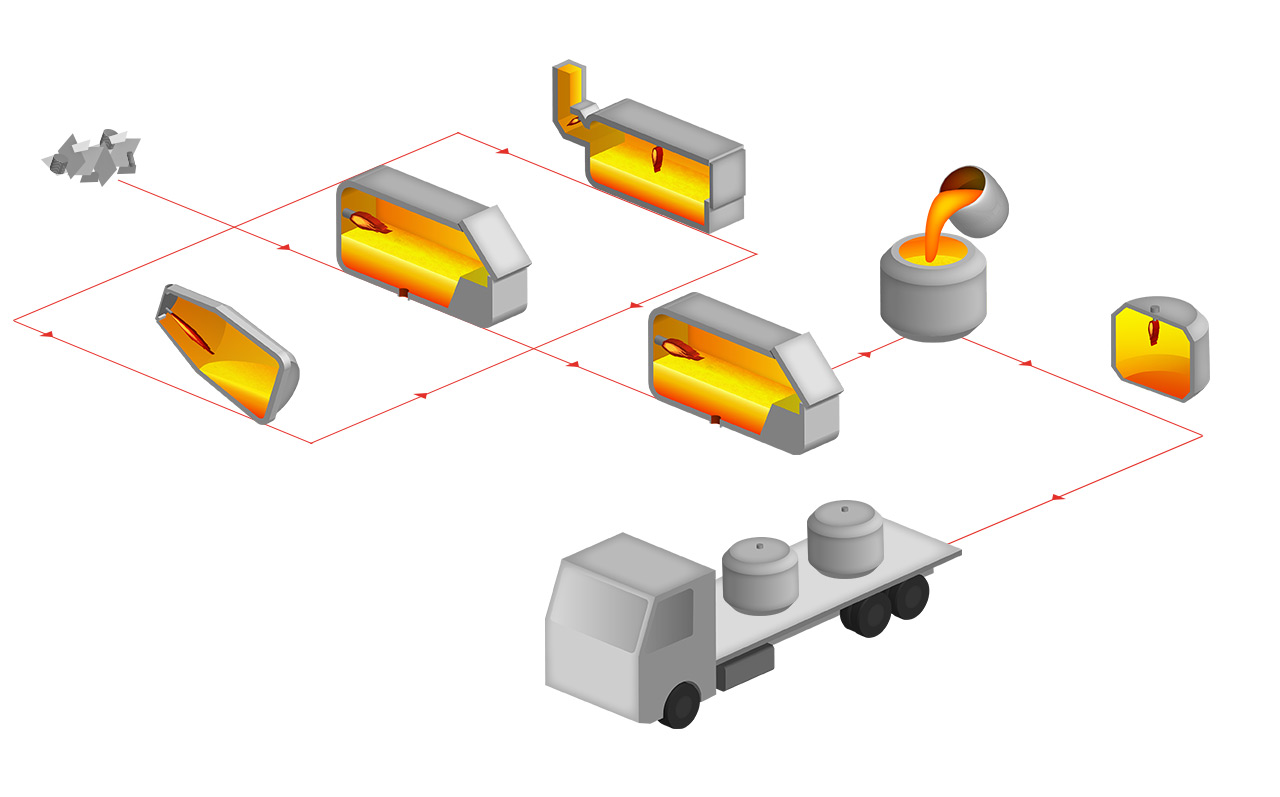

Just over 50% of aluminum products are produced from recycled secondary aluminum, with the main process steps being scrap conditioning, melting and casting. Depending on the contamination and bulk of the scrap, various types of furnace are used during melting: rotary drum furnaces, chamber furnaces or shaft furnaces. To remove impurities, the aluminum melt is cleaned by gas purging. This takes place in holding furnaces or specially designed ladle stations. In the case of the melt being transported in ladles on vehicles to another processing location, it is necessary to preheat the ladles with burners.

Application proposal Solution proposal

Contact form for every page

Contact us

select action